Small Batch CNC Machining

With technological advancements, the uptake of small batch CNC machining has surged, resulting in efficient, precision-focused manufacturing and ensuring quick delivery of products that align with unique customer specifications.

What is Small Batch CNC Machining?

Small Batch CNC (Computer Numerical Control) Machining is a manufacturing process that creates precise parts in smaller quantities, typically ranging from one to several hundred units. It’s a popular choice for prototypes, custom orders, or small production runs where high precision is needed.

The process uses pre-programmed computer software to control the movement of machinery and tools. The computer controls can operate complex machinery such as grinders, mills, routers, and lathes, allowing for high accuracy and repeatability in manufacturing parts.

Small Batch CNC Machining contrasts with mass production that makes thousands or millions of identical parts. It provides a cost-effective solution for low-volume businesses needing high-quality, custom parts. The high customization, rapid prototyping, and reduced inventory costs make Small Batch CNC Machining an attractive option for many businesses.

Time Delivery Rate

Yield

Customer Satisfaction Rate

Advantages of Small Batch CNC Machining

Small batch CNC machining offers numerous advantages: greater flexibility, reduced inventory costs, easier customization, rapid prototyping, and superior precision. These benefits can lead to substantial cost savings and elevated customer satisfaction levels, making small batch CNC machining an attractive option for many businesses.

Greater Flexibility

Unlike mass production, small batch CNC machining allows manufacturers to quickly and efficiently adjust to changes in design or customer requirements. This agility can provide a significant competitive advantage in markets where customer needs, and trends evolve rapidly.

Reduced Inventory Costs

Small batch CNC machining allows manufacturers to produce only what’s needed, exactly when it’s required. This strategic, just-in-time approach minimizes storage costs for finished goods and raw materials, offering significant financial benefits.

Easier Customization

Since each batch is smaller, it’s easier to customize each product run to meet specific customer requirements. This is particularly advantageous in industries where tailored solutions are the norm, such as medical device manufacturing or aerospace engineering.

Superior Precision

CNC machining provides high precision and consistency. This is crucial for manufacturing high-quality parts. In small batch production, each piece can be monitored more closely for quality, ensuring that each part meets the stringent standards required.

Rapid Prototyping

Small batch CNC machining is perfect for creating prototypes. Businesses can test multiple designs, make quick adjustments, and then run a new batch of prototypes, facilitating faster product development cycles.

Cost-Effective for Low-Volume Production

For low-volume production, small batch CNC machining is more cost-effective than traditional methods. It saves on initial setup costs without requiring physical tooling like molds or dies. This makes small batch CNC a cost-efficient choice for small production runs.

Our Services

CNC Milling >

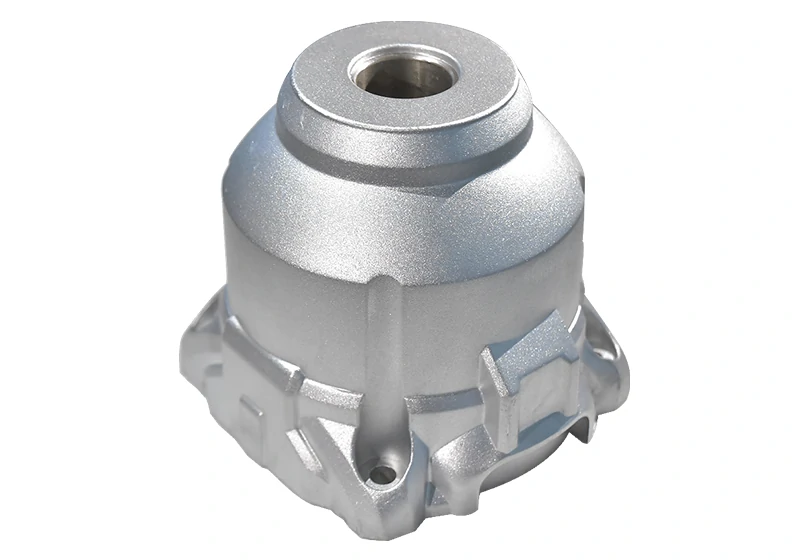

CNC milling manufactures complex geometric shapes and planes for a wide variety of products. Multi-axis metal CNC machine tools do not need to fix the mold, highly flexible, high precision. We have 3 axis, 4 axis, 5 axis machine, can meet the machining demand.

CNC Turning >

CNC Turning process to produce custom cylindrical shape prototypes and end-use production part. We use CNC lathes to machine features like axial and radial holes, flat openings, grooves.

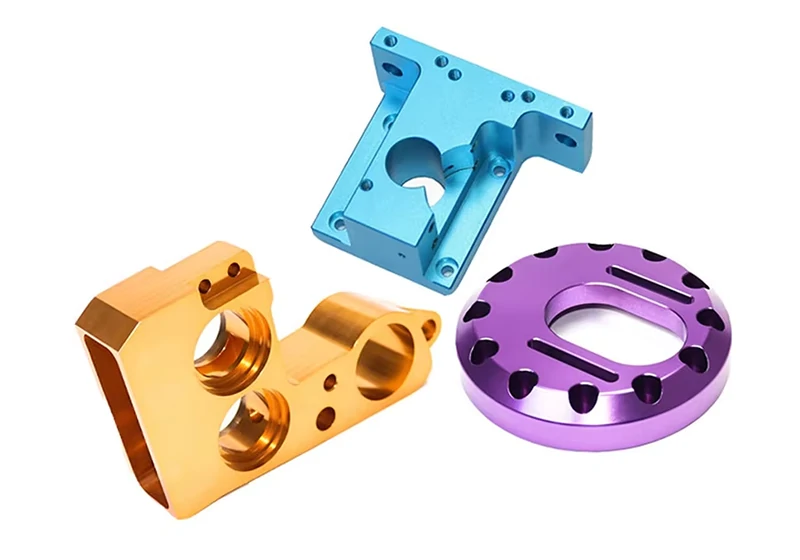

CNC machining materials

Aluminum

2024, 5052, 5083, 6063, 6061, 6082, 7050, 7075

Stainless Steel

17-4, 18-8, 303, 304, 316, 416, 420, 430, 410, 440C, 321, 347

Brass

C36000, C26000, C28000, C37700, C48500, C22000, C23000, C24000

Copper

C11000, C10100, C14500, C17200, C18200, C19400, C10200, C12200

Titanium

2024, 5052, 5083, 6063, 6061, 6082, 7050, 7075

Plastic

POM, ABS, Nylon, PEEK, PTFE, PAI, PMMA, PEI, HDPE, PVC, PPS, PC, UHMW

CNC machining surface finishes

Check The Characteristics of Materials to Choose the Best One for Your Project, Click “View All” to Learn More.

Painting

Applies a colored coating for aesthetics and protection.

Passivation

Enhances corrosion resistance by removing free iron from surfaces.

Powder Coating

Durable, powder-applied finish, baked to form a hard coat.

Anodizing

Electrochemical process creating a shiny or dull, corrosion-resistant layer.

Polishing

Creates a smooth, shiny surface by mechanical abrasion or chemical treatment. (Ra 0.8μm / Ra 32μin or better)

Black Oxide

Black conversion coating providing corrosion resistance.

Sandblasting

Uses high-pressure sand to clean and texture surfaces, creating a matte finish.

Plating

Corrosion resistance, with solderability and electrical conductivity, various material options.

Specialist industries

Aerospace & UAV

Automotive

Consumer Products

Industrial

Medical

Robotics

Request A Quote

Recent Articles/Blog

Metal Surface Finish: A Comprehensive Guide to Metal Finishing Processes

Metal surface finishing processes are treatments applied to metal surfaces to enhance appearance...

Read More →

What is Slot Milling: Types, Techniques, Tips, and Advantages

Slot milling is a machining process where a milling cutter removes material from a workpiece to create slots...

Read More →

Precision CNC Milling Services

This manufacturing process works well for many materials, including metals, polymers, wood and glass....

Read More →

What is Slot Milling: Types, Techniques, Tips, and Advantages

Slot milling is a machining process where a milling cutter removes material from a workpiece to create slots...

Read More →