- E-mail: info@hlhcnc.com

- Tel: +86-189-2523-3140

- Room 202, Building 1, No. 1, Datang Hongfa Street, Dalingshan, Dongguan, Guangdong, China 523835

CAPABILITIES

RESOURCES

ABOUT

Experienced Engineers

Up-to-date Machines

Satisfied customers

Sq/m Manufacturing Facility

Over 20 Years High Precision CNC Turning Experience. We Are A Reliable Manufacturer You Can Trust. Send Your Project to Start Our Coopreation.

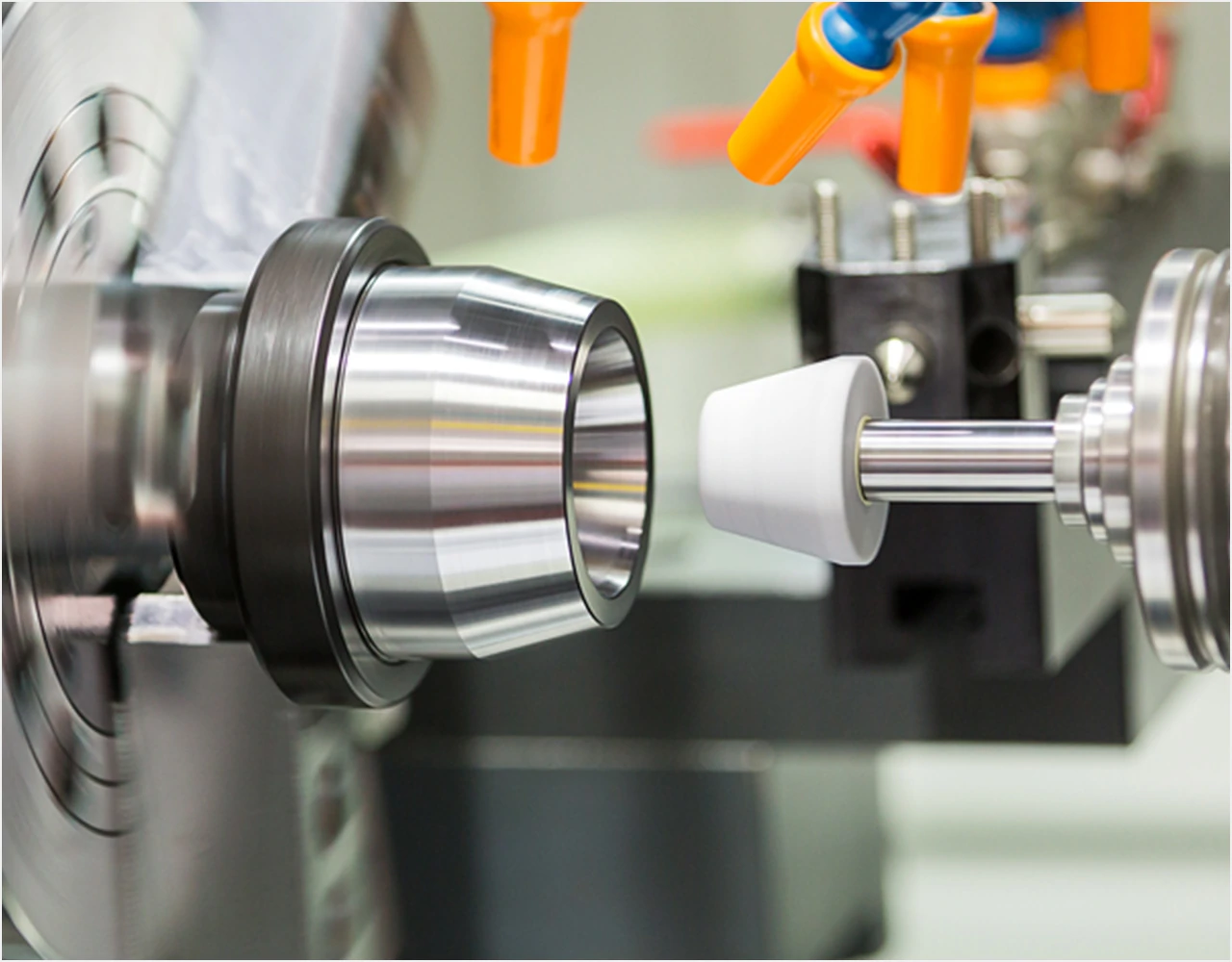

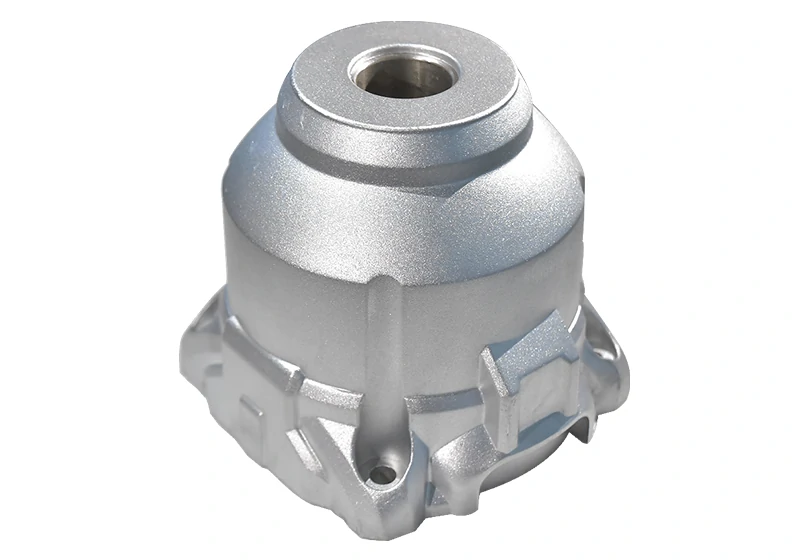

Our CNC turning services provide high-precision, cost-effective solutions for creating your parts. Utilizing state-of-the-art CNC lathes and a skilled team of machinists, we ensure efficient production for both small and large batches. Whether for automotive, aerospace, or industrial applications, our turning services guarantee top-quality, reliable components that meet the most stringent specifications.

CNC turning produces parts by mounting a blank on a rotating chuck and removing material using stationary cutting tools. This technology is ideal for manufacturing parts with symmetry along their center axis. Turned parts are typically produced faster (and at a lower cost) than milled parts.

Quality Assurance

We are certified and compliant with ISO 9001:2015, 99% our customers are very satisfied with our products and services.

Technical Expertise

With advanced machinery and an experienced technical team, we can handle complex designs and specifications, meeting your high-precision machining needs.

Great Lead Time

Our efficient production processes and management systems ensure timely delivery to meet your project deadlines without delay.

Customer Service

We will reply to you within 1 hour after receiving your inquiry. Our professional team will work closely with you from the beginning of the order to the delivery.

Cost Efficiency

Under the premise of ensuring quality, we provide you with the most cost-effective solutions by optimizing material, labor and management costs

Production Capacity

Our flexible production capacity allows us to scale according to your project needs. Whether small or large orders, we complete them efficiently and on time.

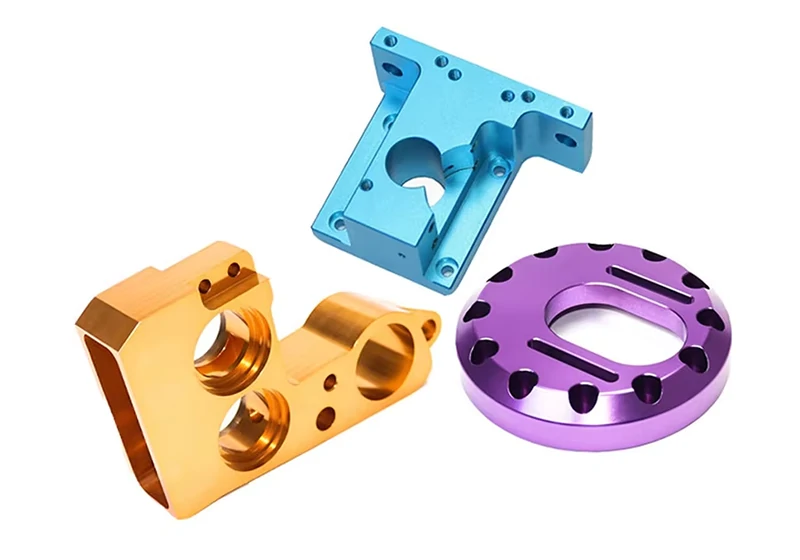

Aluminum

2024, 5052, 5083, 6063, 6061, 6082, 7050, 7075

Stainless Steel

17-4, 18-8, 303, 304, 316, 416, 420, 430, 410, 440C, 321, 347

Brass

C36000, C26000, C28000, C37700, C48500, C22000, C23000, C24000

Copper

C11000, C10100, C14500, C17200, C18200, C19400, C10200, C12200

Titanium

2024, 5052, 5083, 6063, 6061, 6082, 7050, 7075

Plastic

POM, ABS, Nylon, PEEK, PTFE, PAI, PMMA, PEI, HDPE, PVC, PPS, PC, UHMW

Check The Characteristics of Materials to Choose the Best One for Your Project, Click “View All” to Learn More.

Painting

Applies a colored coating for aesthetics and protection.

Passivation

Enhances corrosion resistance by removing free iron from surfaces.

Powder Coating

Durable, powder-applied finish, baked to form a hard coat.

Anodizing

Electrochemical process creating a shiny or dull, corrosion-resistant layer.

Polishing

Creates a smooth, shiny surface by mechanical abrasion or chemical treatment. (Ra 0.8μm / Ra 32μin or better)

Black Oxide

Black conversion coating providing corrosion resistance.

Sandblasting

Uses high-pressure sand to clean and texture surfaces, creating a matte finish.

Plating

Corrosion resistance, with solderability and electrical conductivity, various material options.

Metal Surface Finish: A Comprehensive Guide to Metal Finishing Processes

Metal surface finishing processes are treatments applied to metal surfaces to enhance appearance...

Read More →

What is Slot Milling: Types, Techniques, Tips, and Advantages

Slot milling is a machining process where a milling cutter removes material from a workpiece to create slots...

Read More →

Precision CNC Milling Services

This manufacturing process works well for many materials, including metals, polymers, wood and glass....

Read More →

What is Slot Milling: Types, Techniques, Tips, and Advantages

Slot milling is a machining process where a milling cutter removes material from a workpiece to create slots...

Read More →