- E-mail: info@hlhcnc.com

- Tel: +86-189-2523-3140

- Room 202, Building 1, No. 1, Datang Hongfa Street, Dalingshan, Dongguan, Guangdong, China 523835

CAPABILITIES

RESOURCES

ABOUT

The process of using physics, chemistry, metallurgy and heat treatment to change the condition and properties of the surface of parts to obtain parts that meet precise performance requirements is called surface finishing or surface treatment. Customachining provides you one-stop solution for manufacturing and surface finishing of your custom parts.

Polishing

Polishing refers to the use of mechanical, chemical or electrochemical action to reduce the surface roughness of the product to obtain a bright and smooth surface. It is the modification of the surface of the product with polishing tools and abrasive particles or other polishing media.

Applicable Materials:

PC, PMMA, Steel, Stainless steel, brass, copper, Aluminum, etc

Texture:

Smooth, glossy finish

Surface roughness:

Ra 0.2μm / Ra 32μm

Function:

Reduce product surface roughness, improve product appearancepolishing media.

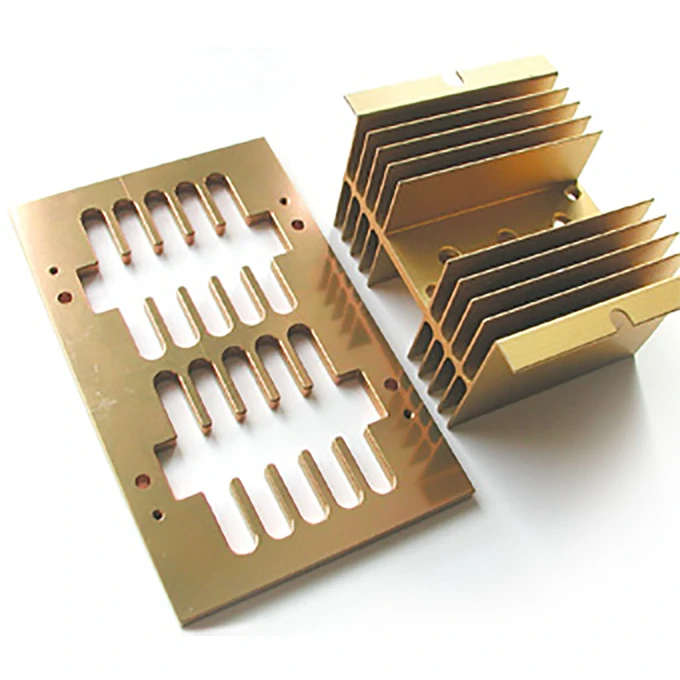

Anodizing

Anodizing refers to the electrochemical anodizing of metals or alloys. Under the corresponding electrolyte and specific process conditions, aluminum and its alloys form an oxide film on the aluminum product (anode) due to the action of the applied current.

Applicable Materials:

Aluminum

Texture:

Any RAL code or Pantone number

Surface roughness:

5-20μm

Function:

Make the products not easy to be scratched, not easy to be corroded

Sandblasting

Sandblasting is the process of cleaning and roughening the surface of the substrate by the impact of high-speed sand flow. Due to the impact and cutting effect of abrasives on the surface of the product, the surface of the product can obtain a certain degree of cleanliness and different roughness

Applicable Materials:

Aluminum , Steel , Stainless Steel , Brass, Copper

Texture:

Natural color of raw material

Surface roughness:

Uniform matte

Function:

Improve the mechanical properties and fatigue resistance of the product, and increase the service life of the parts.

Painting

Painting refers to the surface coating processing of industrial products. Spray the specified color according to the customer's requirements.

Applicable Materials:

ABS,PC,PMMA,Aluminum,Stainless steel

Texture:

Any RAL code or Pantone number

Surface roughness:

Uniform gloss or matte

Function:

Improve the appearance of the product, and extend the service life of the product through an extra layer of protection.

Powder coating

This is a coating process that uses corona discharge to make powder coatings adhere to the product. A wide variety of colors are available to create the desired aesthetic.

Applicable Materials:

Aluminum , Steel , Stainless Steel

Texture:

Any RAL code or Pantone number

Surface roughness:

200-300μm

Function:

Improve product appearance. Make products more wear-resistant and corrosion-resistant.

Chromate conversion coating

It refers to the treatment method of chemically reacting metal with chromate to form a stable chromate film on its surface.

Applicable Materials:

Aluminum

Texture:

Clear, Yellow

Surface roughness:

Tools, hardware, electrical systems

Function:

Increase the corrosion resistance of product while maintaining their conductive properties.

Passivation

Passivation refers to the process in which the metal is oxidized by a strong oxidant or electrochemical method to make the surface into an inactive state.

Applicable Materials:

Steel , Stainless Steel

Texture:

Natural color of raw material

Surface roughness:

Smooth glossy finish

Function:

Make products more corrosion-resistant. Increase the service life of the parts

Zinc plating

This process is done by coating the part in a flux and dipping the part into molten zinc. The molten zinc forms a bond with the steel, creating a protective layer on the surface of the part.

Applicable Materials:

Steel , Stainless Steel

Texture:

Smooth finish

Surface roughness:

Sandblasting, Passivation

Function:

Prevent product surface oxidation or corrosion

Nickel plating

Nickel plating is a process used to electroplate a thin layer of nickel onto a metal part.

Applicable Materials:

Aluminum , Steel , Stainless Steel

Texture:

Smooth finish

Surface roughness:

Sandblasting,Painting

Function:

Make the product resistant to corrosion and abrasion, as well as for decorative purposes

Electropolishing

Electropolishing is an electrochemical process used to clean metallic surfaces and reduce micro-roughness of stainless steel parts. Useful to remove a thin (up to 10μm) layer of material.

Applicable Materials:

Steel , Stainless Steel

Texture:

Smooth, glossy finish

Surface roughness:

Natural color of raw material

Function:

Improve surface finish